What we do

-

![]()

CNC Laser Cutting

Our fiber laser cutting technology allows us to process aluminum, steel, and stainless quickly and precisely. With oxygen, nitrogen, and shop air assist gas options, we can tailor the cut to your material and finish requirements while holding tight tolerances that reduce the need for secondary processing.

-

![]()

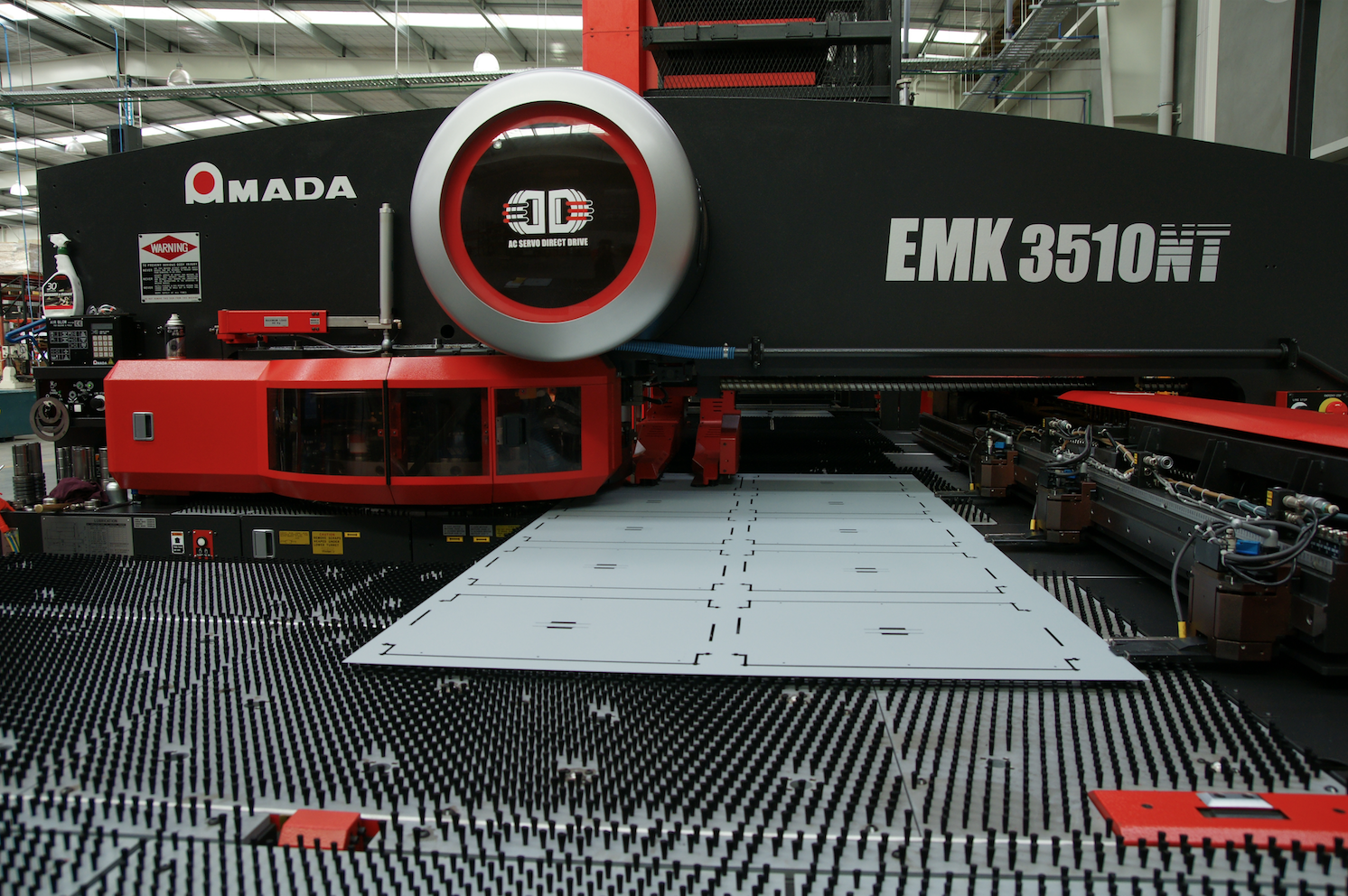

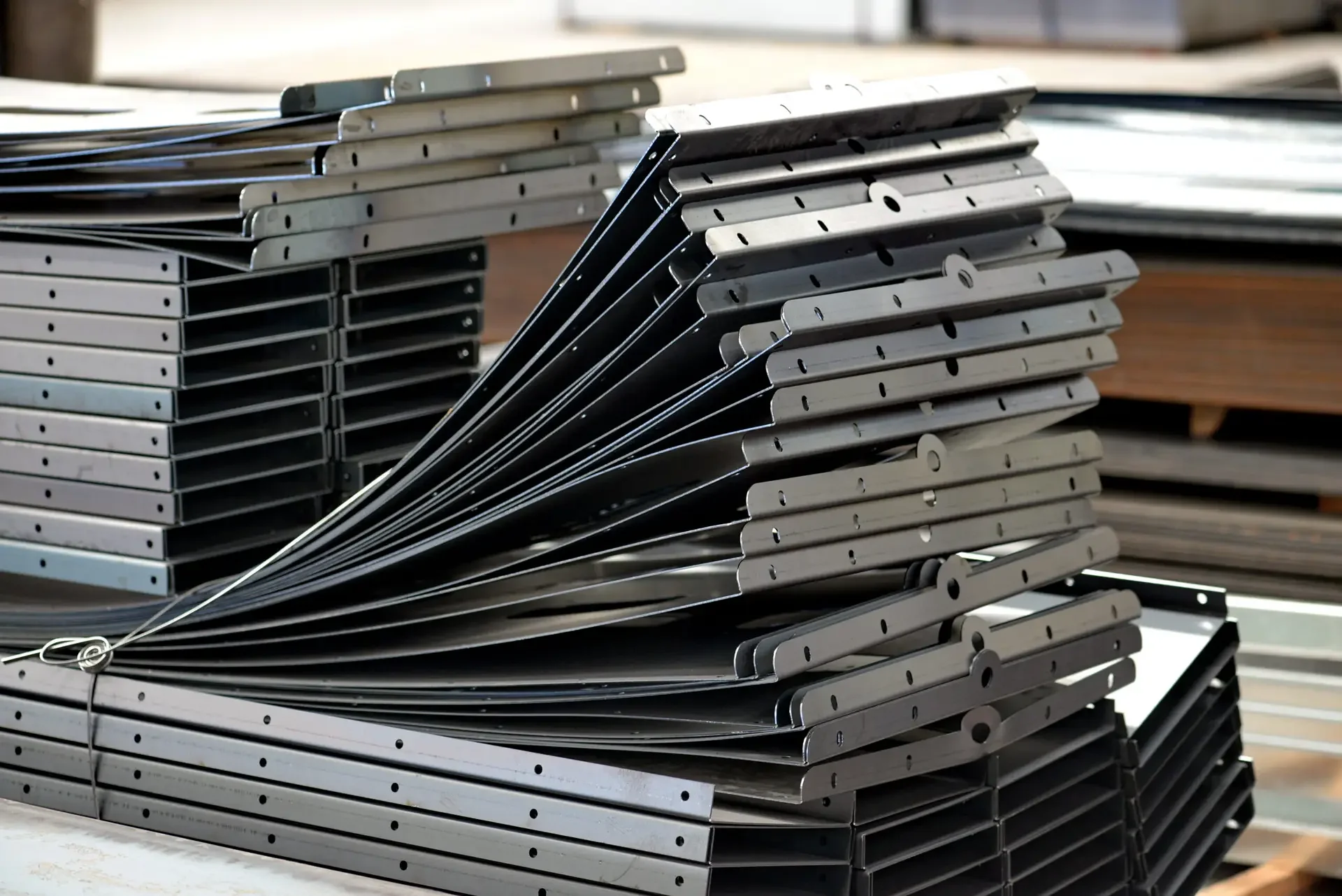

CNC Punching

For parts with counter-sink, louvers, embossing, or formed features, our CNC punching systems provide efficient sheet processing. With a broad tooling library and production-ready programming, we can deliver complex geometries at competitive cycle times.

-

![]()

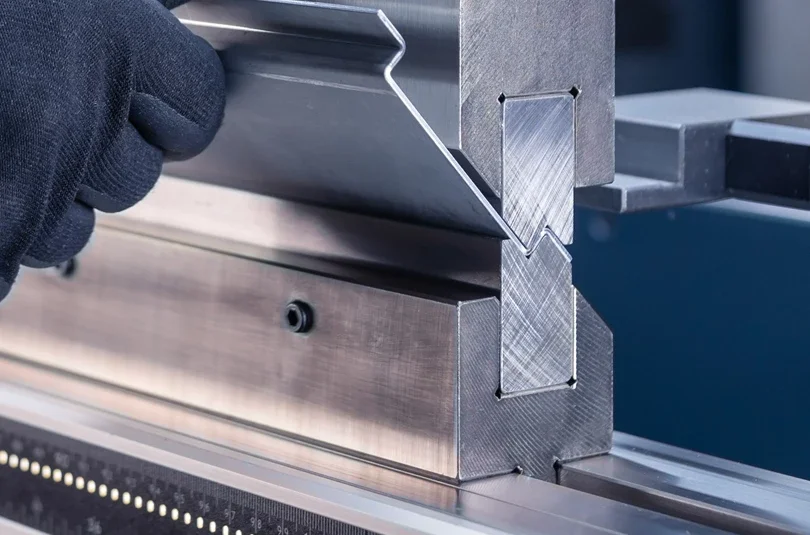

Press Brake Forming

Our press brakes allow for accurate, repeatable bending across a wide range of material. With offline programming to speed up setups, we are able to handle everything from simple bends to complex multi-form parts with consistency and precision.

-

![]()

Welding

Our team provides both MIG and TIG welding services across aluminum, steel, and stainless materials. By combining skilled welders with fixture-based setups, we ensure accuracy, strength, and repeatability for every welded component.

-

![]()

Assembly

Beyond individual components, we support customers with complete assembly services. This includes subassembly work, hardware insertion such as PEM fasteners, standoffs, and rivet nuts, as well as final fit checks to make sure everything performs as intended.

-

![]()

Finishing & Coating

To ensure every part looks and performs as intended, we provide deburring, sanding, and hardware installation in-house. For powder coating and specialty finishes, we partner with trusted local finishing suppliers so you receive a turnkey product.